Robust damper design for multiharmonic excitation under flexible operations

| Led by: | Lars Panning-von Scheidt |

| E-Mail: | brinkmann@ids.uni-hannover.de |

| Team: | Katharina Brinkmann |

| Year: | 2024 |

| Date: | 01-10-23 |

| Funding: | AG Turbo |

| Duration: | 01.10.2023-28.02.2027 |

Project describtion

As a result of the increase in renewable energy conversion, the future and current power plant portfolios need to be flexibilized, as they must be adapted to the volatile nature of renewable energy sources. In addition to the operating and the fuel flexibility, the highest efficiencies of the power plants and their components are still required throughout this sector. As a consequence, the unavoidable application of partial load or the use of hydrogen as a future medium in the gas turbines considered in this project may result in vibrational loads on the turbine blades due to frequency spectra downstream of the burners, which are considerably more broadband. This also entails the risk of further excitation mechanisms and frequencies acting on the rows of blades downstream of the combustion chamber. Underplatform dampers, which dissipate some portion of the kinetic energy of the vibration via friction, are used to prevent excessive vibration loads on the turbine blades. Usually, these are optimized for one operating point and thus one oscillation mode or one nodal diameter. The aim of this research project is therefore to establish design rules for frictional elements that are robust against so-called multi-resonances, i.e. that the excitation forces occurring at one operating point simultaneously excite different vibrational modes and/or different nodal diameters.

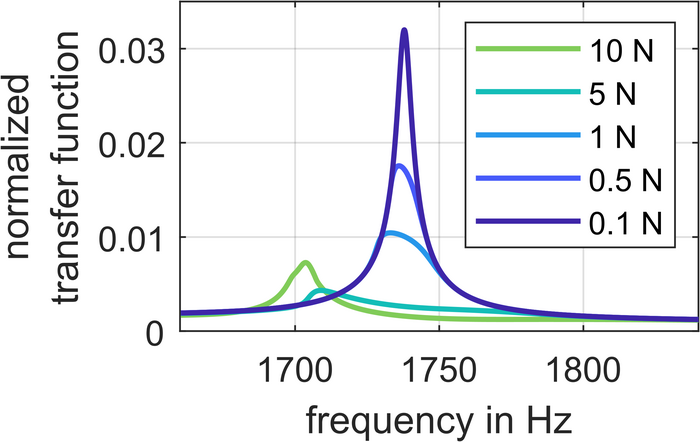

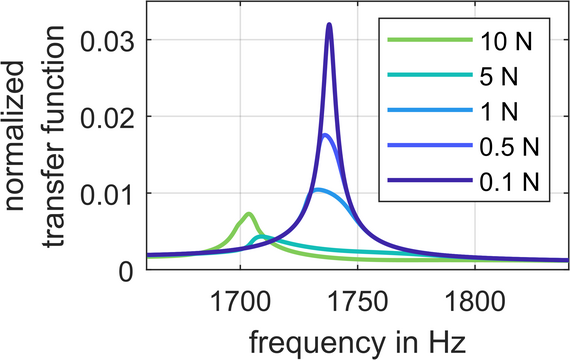

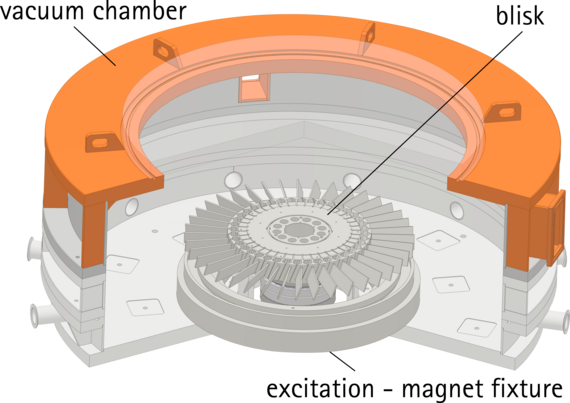

In order to accomplish this, an existing simulation tool is being enhanced to predict the vibration amplitudes of turbine blades coupled via friction dampers (see Figure 1) under multi-harmonic excitation. A precise prediction of this non-linear dynamic load and consequently of the lifetime of a turbine blading is thus targeted, as well as an experimental validation of these simulations within realistic operating conditions under rotation.

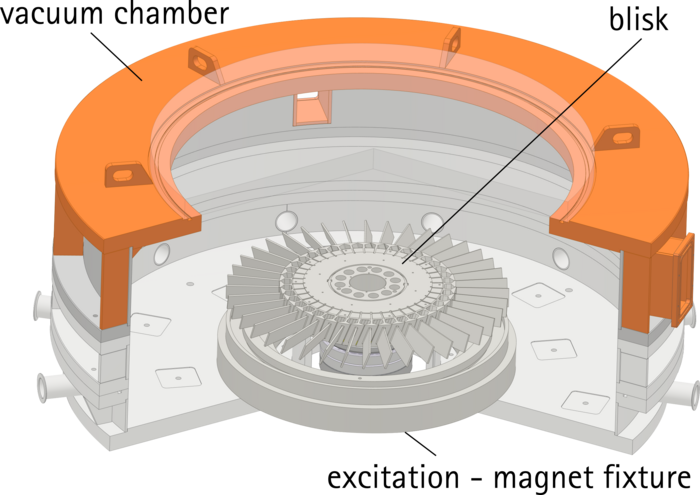

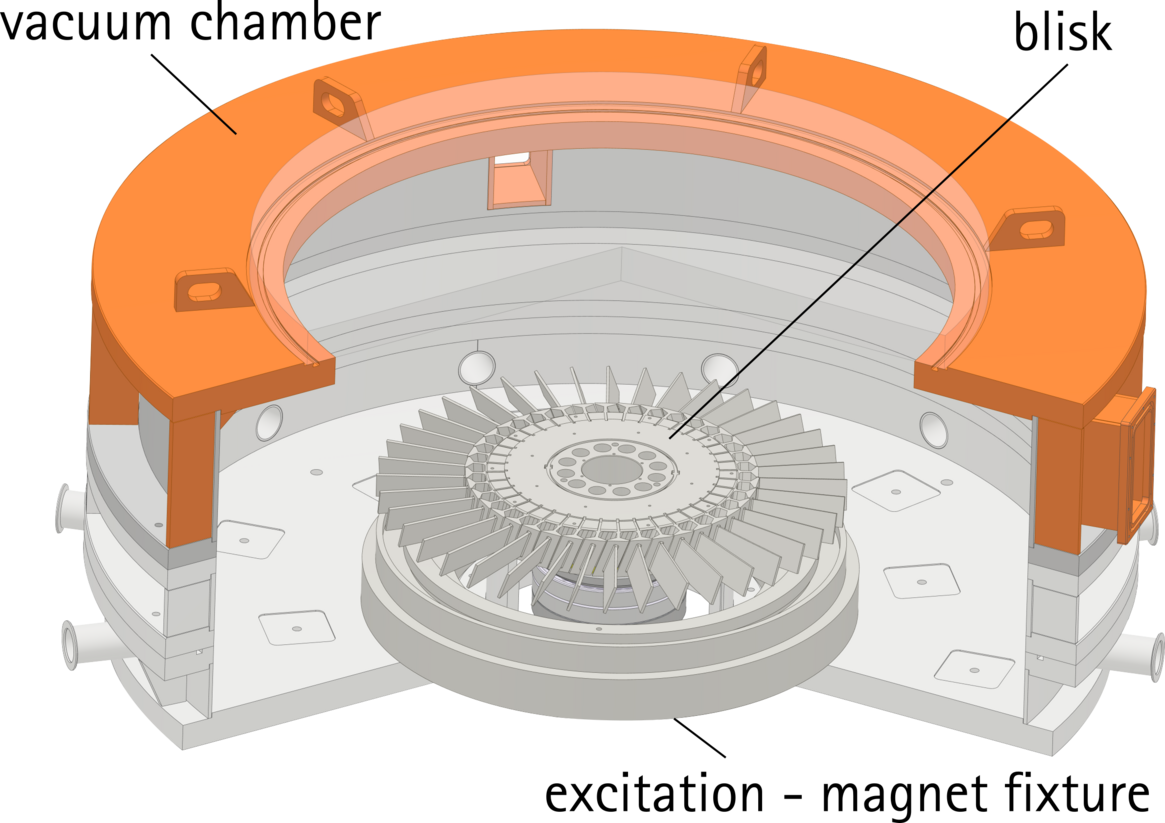

For this purpose, the Institute's rotational test rig (see Figure 2) is being modified to include a variable multiharmonic excitation for the purpose of investigating different operating points and combinations of possible multiresonances.